Product Description

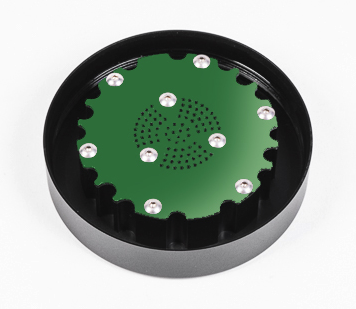

Radium Engineering Universal Air Oil Separator-Returns (AOS-R)

Click here to download installation instructions (PDF)

A high powered modified engine tends to generate excessive blow-by oil and gasses. In these cases, an ordinary small catch can may quickly fill with oil and not be adequate. Like the Radium Engineering Catch Cans, the AOS-R (Air Oil Separator, Return) is responsible for keeping blow-by oil and other pollutants out of the air intake, intercooler, manifold, etc. The main difference is that an AOS-R system returns oil back into the pan above the oil level. This permits a service-free system.

IMPORTANT INSTALLATION NOTES:

-For the AOS-R to function properly, a return port on the engine must be available on the engine to the oil pan.

-The AOS-R must be mounted high enough in the engine bay so that the port on the bottom is higher than the engine return port.

-For heating purposes, engine coolant must be routed to the AOS-R to prevent condensation.

Without a properly designed air oil separator, water condensation can develop and find its way in the oil pan contaminating engine oil.

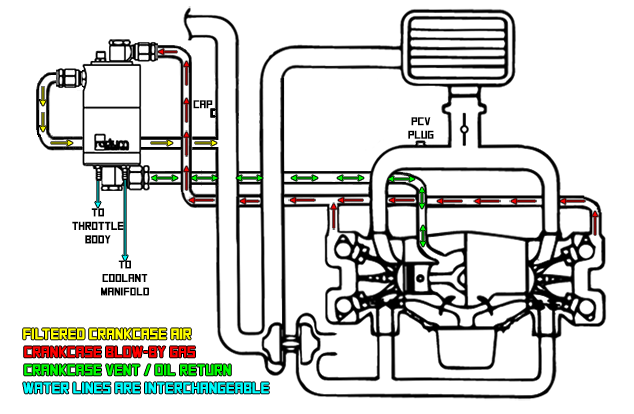

Engine coolant lines are routed through the Radium Engineering AOS-R via the 2 barbed fittings. The coolant enters a specially designed heating chamber (shown below).

This keeps the AOS-R warm and prevents internal water condensation. Because water is more dense than oil, there is an integrated water trap found around the bottom perimeter that prevents condensation from descending into the oil pan. With a properly operating system, the fluid level inside the AOS-R will be empty after sitting. If there is a possible return obstruction, simply unscrew the AOS-R dipstick for inspection. Conversely, the entire billet unit disassembles into 3 large pieces for servicing.

For plumbing, the valve cover vent(s) are routed into the AOS-R inlet where stainless steel condensing material (shown below) separates the oil from the gasses.

The filtered liquid oil is collected at the bottom of the AOS-R and drawn into the oil pan. Meanwhile, the clean crankcase air can either vent-to-atmosphere (VTA) or vent-to-engine (VTE). Shown above is a plumbing example for the 20-0219 AOS-R, Universal VTE. All of the plumbing in the example above also applies to the 20-0819 AOS-R, Universal, VTA except for the yellow hose. This line is not required as the VTA unit vents-to-atmosphere through the top of the can.

Benefits

-Lowers hydrocarbon emissions

-Effectively raises the octane and increases engine performance with cleaner inlet air

-Prevents oil buildup in the intake or intercooler system walls, throttle body, intake manifold, etc

Included

-Machined alumium Radium Engineering AOS-R

-Aluminum mount that permits 360 degree rotation

-Two 5/16" barbed fittings for coolant lines

-Stainless steel hardware

Ports

Inlet Port(s): 7/8"-14 threaded for 10AN ORB fittings

Outlet Port (VTE only): 7/8"-14 threaded for 10AN ORB fittings

Return Port: 7/8"-14 threaded for 10AN ORB fittings

Coolant Ports: 7/16"-20 threaded, includes two 7mm (or 5/16") barb fittings

Measurements

AOS-R Height: 6.7" (without fittings)

AOS-R Diameter: 3.45" Round

AOS-R Capacity: 20.3 oz (600mL)

*If operated in freezing environments, Radium Engineering recommends installing insulation sleeving (not included) over any hose exposed to cold air flow. This will help prevent the natural phenomenon of water condensation freezing and potentially clogging the hose.

20-0219 AOS-R, Universal, VTE

The vent-to-engine air-oil separator has a top (inlet) and side (outlet) port. The outlet port should be routed back into the intake or turbo inlet pipe. The VTE system is a must for mass-air flow (MAF) sensor engines. Furthermore, the VTE AOS-R will not expel an undesireable gas scent into the cabin. Lastly, the VTE system will prevent any potential oil debris from coating the engine bay.

The included mounting bracket (shown above) permits 360 degree rotation.

20-0819 AOS-R, Universal, VTA

The vent-to-atmosphere air-oil separator has 2 side (inlet) ports. This is great for dual bank engines that have 2 crankcase vent ports.

NOTE: For single crankcase vented engines, simply plug one of the inlet ports with Radium Engineering 14-0351.

The VTA AOS-R features one giant non-restrictive outlet that is over 183% larger than the inner diameter of the 10AN inlets. This increase in volume slows air flow allowing contaminants to fall out of suspension. Additionally, contaminants are trapped with a diffuser permitting the oil sludge to fall back into the catch can preventing overspray in the engine bay. Furthermore, it is a dual stage design (located in the inlet and outlet). These free flowing chambers do not create any flow restriction.

The included bracket system (shown above) provides a ton of flexibility and permits full 360 degree rotation.

Additionally, M6x1mm hardware is provided for chassis mounting.

NOTE: Because of the vented "air leak" in the system, the VTA AOS-R is not recommended for mass-air flow (MAF) sensor engines.